Bawtry & East Cowton

Re-ballasting Works

Network Rail Works Delivery

Smarttrax were asked to devise a plan to undertake re-ballasting works at both Bawtry and East Cowton on the East Coast Main Line by Network Rail. Both sites had failing formation in and around back to back crossovers. All remaining components were to be re-used.

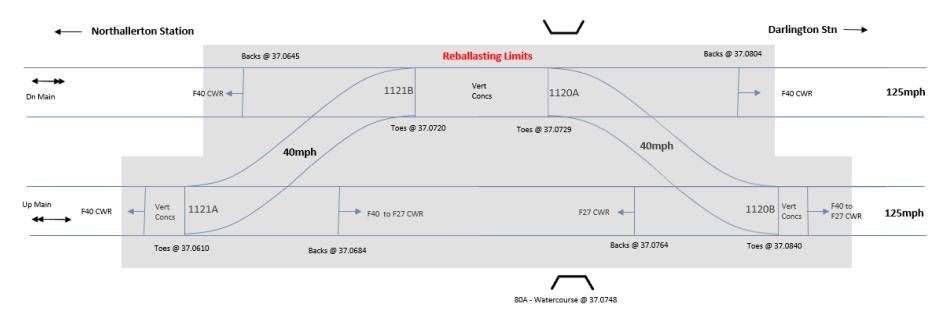

View Diagram 1 View Diagram 2 View Staging WK 34Example spec from East Cowton below:

Following initial site surveys plans were completed as below:

- Undertake re-ballast works on 1 x X-over per 52hr weekend

- Break each crossover into individual panels – leaving crossings and all long timbers as 1 panel

- Utilise PEM/LEMs to remove crossing panel and walk into prepared area in cess

- Use Kirow 1200 to remove remaining panels from the Down Line and stack

- Skim dig crossing panel area on the Up line and install temporary panels to create haul rd

- Complete excavation/formation works and reballast of the Down line

- Reinstate permanent panels to the Down line.

- Remove panels from the Up line and stack

- Kirow to cross lines

- Transfer temporary panels from The Up to Down line

- Complete excavation/formation works and bottom stone of the Up line

- Remove temporary panels

- Reinstate crossing panel with PEM/LEMs

- Install closure rails as required in plain line

- Top stone and tamp

As well as the initial plan Smarttrax were responsible for:

- Ballast calculations

- Haulage planning

- Plant requirements

- Detailed bar charts for all works

- Detailed staging of works

- Welding plans

- Stressing plans

- Creating 3D formation files

- Creating geometry files for tamping

- Engineering cover for all shifts

- Site management during all core works

- Provision of all engineering equipment including Trimble survey and machine control

- CRT assessments

- Track hand backs

- Collation of health & Safety files

All the planned works during 4 x 52 hr possessions were completed as planned and within timescales, ensuring that the lifespan of the cross overs were increased without the costs of a full S & C renewal including new components.

Removing crossing panel with PEM/LEMS

Installing temporary panels with Kirow 1200

Installing crossing panel with PEM/LEMS

Track reinstalled following formation works and reballast